ANGI Energy in partnership with Gilbarco Veeder-Root

Driven by a commitment to reducing carbon emissions, we combine the expertise of Gilbarco Veeder-Root, with over 150 years in refueling technologies, and ANGI Energy, with 40+ years in compressed gases. Together, we offer innovative solutions that empower environmentally conscious consumers and businesses.

Station components

Inlet gas dryers

- Standard and custom designs

- Dew-point detection available

- Regenerating and non-regenerating

- Manual and fully automatic regeneration

Compressors

Modular design with sound attenuated enclosures are available for outdoor weatherproof protection. Integrated systems can include the inlet gas dryer, storage, and priority panel mounted on the compressor skid.

Learn more

Valve panel

ANGI Energy designs and manufactures priority panels for systems filling a few vehicles to very large systems filling thousands of vehicles per day.

Learn more

Storage

ANGI offers various storage configurations, including large and small vessel ASME options for high-pressure applications. Spheres are also available, with all vessels equipped for safety and configurable for multiple operations.

Learn more

Dispensing

ANGI offers various high quality dispensing options for single or dual hose applications.

Learn more

System controls

ANGI Energy provides advanced control packages utilizing PLC and microprocessor technology, tailored for compression and NGV applications.

Learn moreSeamless installation starts here

Before CNG station systems ever leave our facility, they're tested under real-world conditions, your conditions. Our state-of-the-art CNG testing facility ensures every system is validated at your specified suction and discharge pressures using compressed natural gas. This means a smoother installation, faster commissioning, and total confidence in performance from day one.

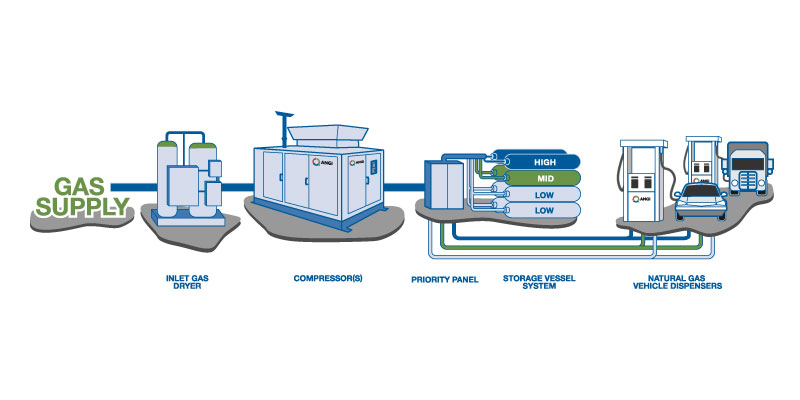

Standard fast-fill station design

Typical fast-fill stations take natural gas from a utility pipeline, compress it, and dispense it into natural gas vehicles or NGV’s. ANGI has designed standard CNG stations for fleets of all sizes, as well as a range of various sizes for public fueling.

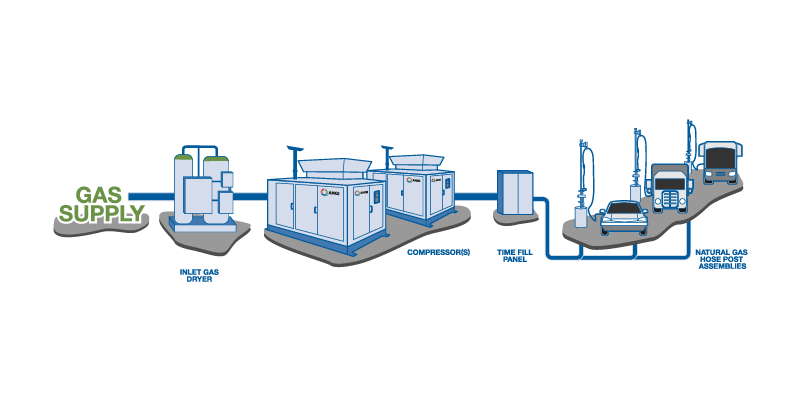

Time-fill station design

Time-fill stations are used to fill multiple vehicles over a longer fueling window. Extended fueling periods reduce the demand of gas flow and lower the cost of compression equipment. Time-fill systems often fill vehicles overnight when the cost of electricity is lower. Centrally fueled fleets such as school buses, refuse vehicles, and utility service vehicles are excellent candidates for time-fill systems.

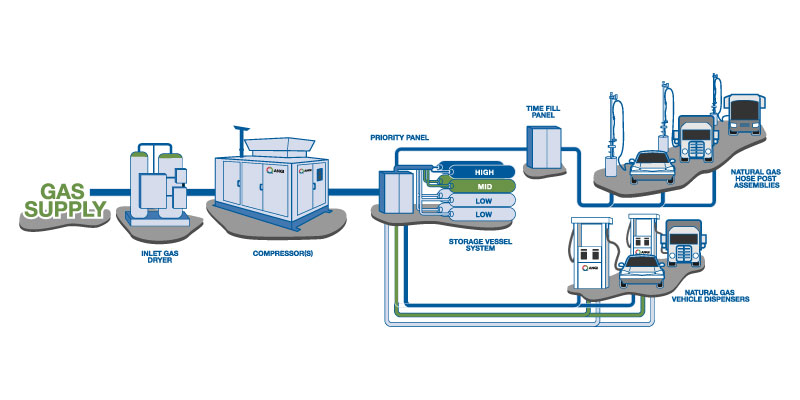

Combination fill station

Combination stations employ the features of a fast-fill and a time-fill station. The most efficient fueling method is to perform fast-fill dispensing during the daytime hours and time-fill overnight. This combination allows high utilization of the station’s compression capacity.

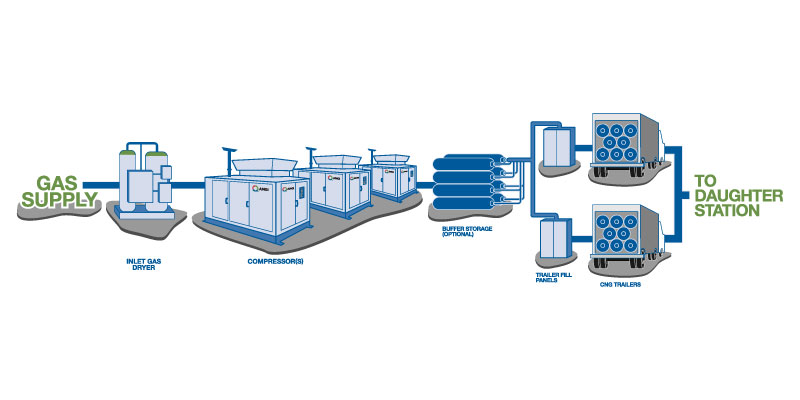

Mother station

Mother stations are used to fill large volumes of CNG into mobile tube trailers The CNG is then transported via a virtual pipeline. A mother station will generally be located near a natural gas supply or a utility pipeline. Mobile storage allows transportation of natural gas to a site that does not have access to natural gas. Typical applications where mother stations are used are to supply gas: daughter stations, industrial gas uses, and gas distribution systems.

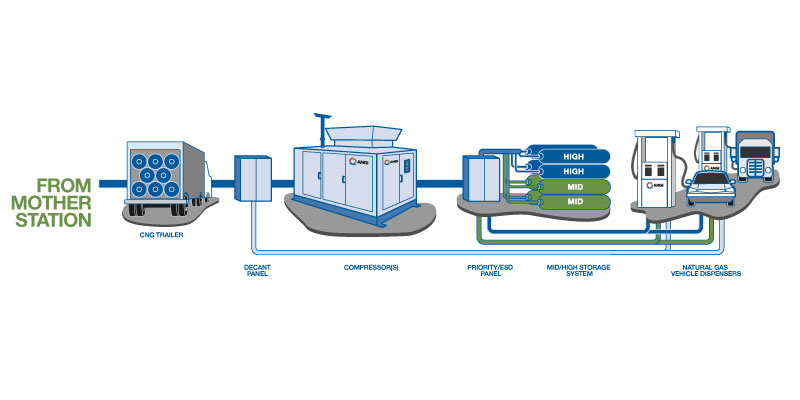

Daughter station

Daughter stations are established at locations where a CNG filling station utilizes mobile CNG storage from a mother station as its fuel source. These stations play a crucial role in the distribution of compressed natural gas, especially in areas where access to a natural gas pipeline is limited.