Compression and decompression for tube trailer filling & pipeline injection

ANGI Energy offers innovative tube trailer solutions for gas compression and decompression, specifically designed for pipeline injection and efficient tube trailer filling. Whether you need to optimize filling processes or control decompression for pipeline integration, we provide the reliable solutions you need to succeed in the evolving energy landscape.

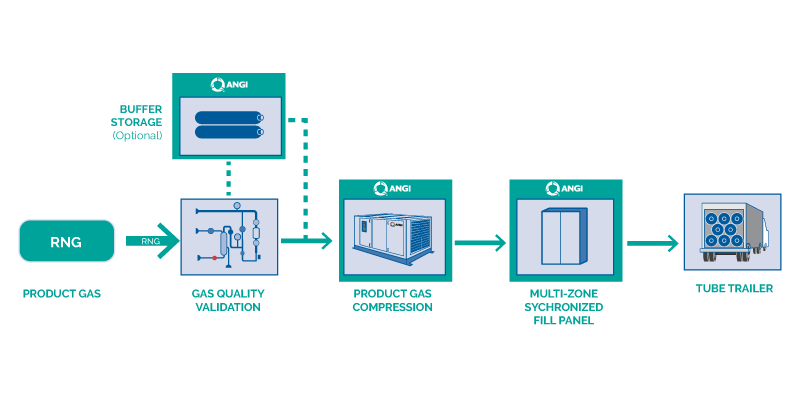

Tube trailer compression

ANGI Energy's reciprocating compressors are expertly designed for tube trailer compression, making them ideal for 250+ psig pipeline injection and filling. This technology efficiently fills tube trailers with high-pressure renewable natural gas (RNG) or compressed natural gas (CNG), ensuring safe and compact storage and transport. With a focus on quality and safety, our engineering incorporates advanced safety features and rigorous testing standards, providing reliable solutions for transporting RNG.

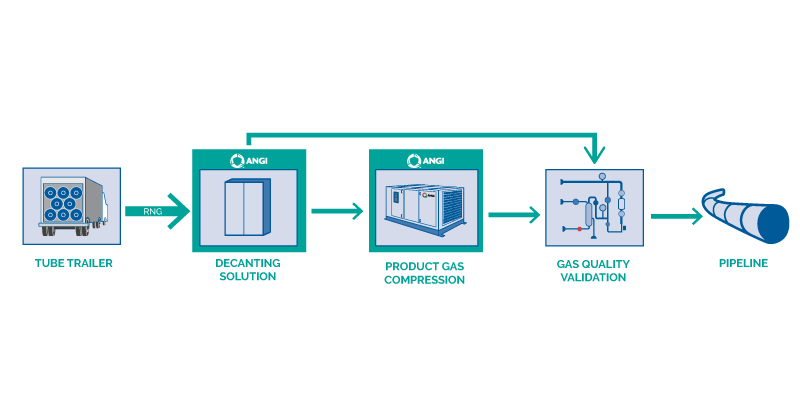

Tube trailer decompression

Safely deliver product gas from a high-pressure transport trailer to a pipeline using a controlled decompression (decanting) process. This involves offloading compressed gas from the tube trailer into a storage vessel or directly into a pipeline at a lower pressure. Specialized equipment, such as offloading and decant panels, efficiently reduces the gas pressure to a usable level. Our decanting systems are suitable for various applications, including CNG fueling stations, virtual pipeline projects, and connecting renewable natural gas (RNG) to the natural gas grid.

Why ANGI Energy?

40+ years' experience

With over four decades of expertise in the compressed gas industry, ANGI Energy delivers unparalleled knowledge and reliability to every project. Our extensive experience ensures we understand the unique challenges and requirements of gas compression and transportation.

High ITC domestic content

Our commitment to high ITC (Investment Tax Credit) domestic content means that a significant portion of our products is sourced and manufactured in the United States.

Maximum uptime

ANGI Energy focuses on maximizing uptime by delivering reliable, high-performance compression systems designed to reduce downtime and enhance operational efficiency. Our state-of-the-art testing facility rigorously evaluates each unit to guarantee optimal performance prior to deployment.

Global footprint

Our global footprint allows us to deliver innovative and reliable solutions worldwide. Our sister company, Gilbarco Veeder-Root, has manufacturing in Salzkotten, Germany, and a network of partners and offices throughout Europe, enhancing our capability to meet the unique needs of various markets.