State-of-the-art solutions to meet your net-zero goals

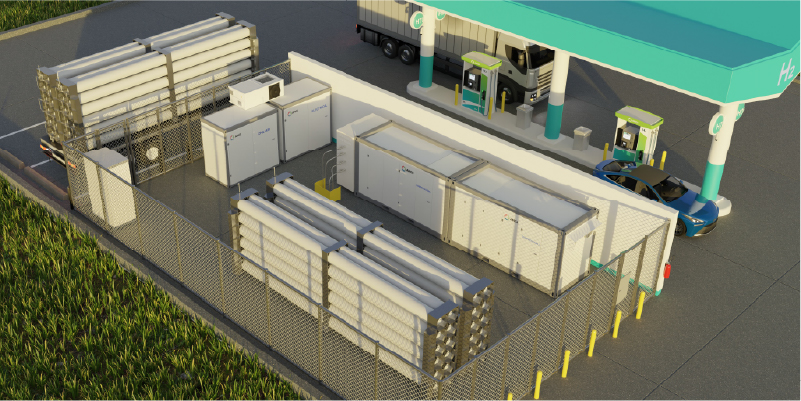

- Modular, containerized solutions for plug and play deployment, even where space is limited.

- Cloud connectivity via central site controller for remote monitoring, reporting, energy management and preventative maintenance.

- Flexible around different hydrogen production or supply models.

- Configurable to serve a wide range of applications across public and private refueling locations.

- Compliant with SAE J2601, SAE J2601-2, and SAE J2601-5 fueling protocols for safe refueling of light, medium and heavy duty vehicles.

- Ready to meet to meet all applicable regulatory and industry certifications by region.

Your partner for the journey

Expertise and proven reliability

Gilbarco Veeder-Root’s 150+ years in retail fueling combines with ANGI’s 40+ years in compressed gas solutions to deliver an innovative and reliable refueling station.

Maximum uptime

Designed for maximum serviceability and uptime, backed by our extensive service & maintenance network.

Consultative station design

Our Hydrogen Specialists work with you to design your station according to your current and future needs.

Cloud connectivity

Cloud connectivity via a central site controller for remote monitoring, reporting, energy management and preventative maintenance.

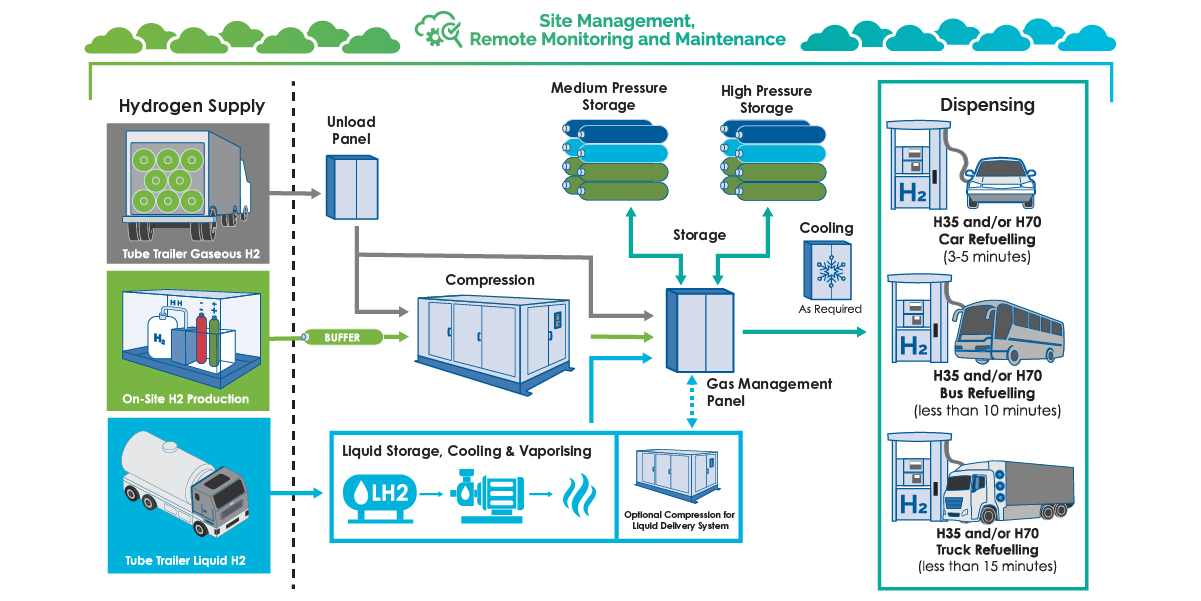

System components

Dispensing

Delivers hydrogen fuel to vehicles at either 350 bar or 700 bar. User friendly interface for a familiar refueling experience.

Gas management panel

The interface between system components which controls the flow of gas on the station.

Storage

Above ground high pressure storage cylinders. Available in 500 bar or 1000 bar, and in multiples depending on your site throughput.

H2 cooling

Chills gas warmed during the compression cycle(s) ready for storage and dispensing.

Hydrogen powered vehicle

Hydrogen is dispensed into hydrogen tanks on the vehicle powered by either ICE (Internal Combustion Engine) or FCEV (Fuel Cell Electric Vehicle)

ANGI portal

Provides real-time & historical insight to equipment performance & predictive analytics to control costs, and provide industry leading uptime.